| Design Team |

Our in-house design, tooling and custom molding services

add values in a variety of dimensions. We have experts in

part design and development that can provide assistance

to your next program. From concept through tooling to actual

injection molding of the finished part, we can ensure the

fastest and most cost-effective route for you to market.

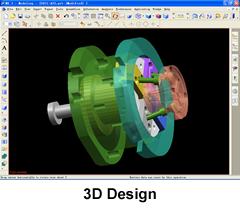

We own a batch of skilled designers who are proficient

in the design software such as UG,Pro-E, Solidworks etc..

We can really express the design purpose of our customer

from design idea to the form of products concept, then to

one time molding of metaphase construction assembly. |

|

|

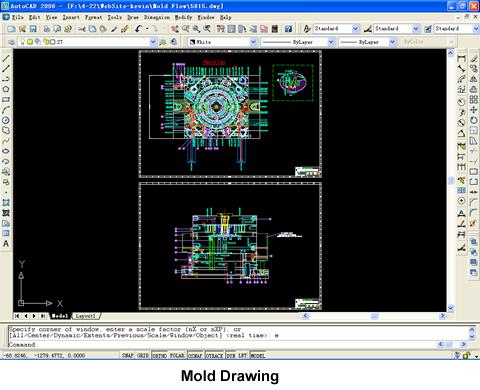

| The product construct design is the important process to

active the function of the new model. The design is not only

meet a demand for the product's style, but think about the

post treatment from the tooling to the finishing such as assembly,

painting, spraying oil, tooling design and manufacture, etc.

All the designs are finished on the computer and the designs

are validate finally through RPM rapid prototyping technology.

Make your new product share and hit the market quickly in

a shortly development cycle. We can offer a shorter lead-time

to put your product to the market ahead of the top companies.

We own the most advanced 3D structure design software such

as PRO/E, UG, SOLIDWORK etc. so we can use all the digital

controlling from design to fitting check interposition, correct

the mold design to save the time of repeat work in developing.

Our engineers collaborate closely with our customers on

all aspects of the programs so as to develop the best designed

molds that are easy to maintain and plastic components that

are cost-effective to produce.

|

|